If you are too lazy to read that much or just want to see what this sounds like, sign up to our newsletter with your best email and we will send you the video of the Agile Spain 2023 Conference talk:

8 Levers for system improvement

Before I start talking about levers, I would like to comment that there are two types of systems. Those pursuing resource efficiency and those pursuing flow efficiency.

2 types of organizations/systems

All organizations seek optimization in two distinct ways.

The first aspect is resource efficiency.

What we are looking for here is that all the elements, all the people are occupied as much time as possible. I don’t care if they deliver or not. I want people to be busy, I pay them a salary for a reason.

And then we have another type of systems which are systems that are focused on achieving flow efficiency. Here the teams, the departments, the company are organized to try to deliver value in the shortest possible time. If anyone wants to go deeper, I recommend this book, it reads very easy and the truth is that I tell a little more about it.

That said, I have a question for you guys which would be:

What type of system do we prefer?

Moreover, as a user, how many of you prefer your system to be resource efficient?

(the answer is always situation 2)

I am going to introduce you to 8 levers that in our experience can work to help systems become more efficient.

1st Efficiency: Visualizes and limits work in progress

When there is an excess of work in progress, when we are working on a lot of things, what will happen is that the team will not have a clear idea of what the priorities are. This, in addition, will cause the team to be changing context with the subsequent penalty in its concentration and, of course, will lower productivity.

What can I do here?

First of all Visualize ALL, in capital letters, the work.

Make it visible. No hidden agendas.

There is not one thing that is in one place, the other is in another.

No! Everything in the same place and all visible.

The next action, limit the work in progress to the available capacity. There are many companies that limit work in progress, okay? But what’s going on? There are 8 of us in the team and we have a WIP of 25. That doesn’t make sense!

In other words, we must seek to limit the work in progress according to our capacity. Always looking for a bit of tension that encourages collaboration. If not, it is of no use to us either. We have a WIP already, but if you never reach it, it’s a sign that we’re doing something wrong.

2nd Efficiency: Focus on bottlenecks

A bottleneck is a point in our system where elements stop flowing as they did before. We will recognize them because things always accumulate before a bottleneck. Why is there an approval from I don’t know who? Why should we plan for a team? All this can be a bottleneck.

A bottleneck, in the end, will restrict the productivity of our system.

What can we do when faced with a bottleneck?

Well, first of all, identify them. Because many times we know that work accumulates there, but we must make visible the amount of work that is waiting there. And this we connect with the first lever. Let’s see where our elements are. Because in the information age, in the end it’s all bytes and you don’t know where they accumulate. If it were physical it looks great because they stack up, but if it’s not physical, we need a JIRA or a KANBANIZE, wherever, we don’t see it.

So, faced with a neck and back, and once identified, we have four options:

- First choice, works faster. That may work sometimes, but sometimes it won’t work, because if you work faster, the probability of making mistakes is higher, the quality will go down, so it’s something that can’t work all the time.

- Second option, increase the capacity of the system, put more people. Well, sometimes it will work for us; however, other times it won’t work for us. You know that phrase? One pregnant woman for nine months is not the same as nine pregnant women for one month. We will not have the same result. Therefore, adding more paper to the printer does not mean that we will print faster. So what do we do, Victor? Well, there are the other two, which are the difficult ones. The other two are…

- Manage the bottleneck. Understand what your process is like. See what activities are performed at that bottleneck that you can subjugate to previous and next steps. Why are we doing it this way? Can we break down what is happening here into other steps?

- And finally, analyze your entire claim. Does your entire claim have to go through all the points? Can’t there be anything to bypass the bottleneck?

3rd Efficiency: Minimizes transfers and dependencies.

What is the problem? That, if we have a lot of dependencies and a lot of hand-offs, our teams will have delays, they will have waits, they will have interruptions of, hey, that thing you did two months ago, remember? And all of this is going to minimize, it’s going to negatively influence the productivity of our teams.

What can we do here?

Well, first of all, visualize.

Victor, did we visualize everything? Yes, the answer is always YES. Our brain works with images, therefore: we visualize EVERYTHING!

Visualizing is superpowerful. So, let’s start with this. Let’s visualize where the dependencies are, who they are between and how often.

Once we have visualized it, what can we do? The mythical organizes people around courage. We see who contributes to the different steps of a process and put them together to collaborate. That’s great. If you can do this it’s great, but it won’t always be possible for us.

We have another option to attack this lever, which is to take action.

What does it mean to take action? We change processes. Let’s change the design of what we are doing. Let us not consider that a process is just the way it is.

Well, “and who designed this process?” “someone someday…”

Then we change it. It’s about adapting, it’s about change.

Watch out!!! We will always need a sponsor to change a process. If there is no Sponsor, then with the story that we have of the agility, we do a test to see how it goes. And well, if it goes well, then that’s what we take with us.

4.a Efficiency: Getting feedback.

The fact that we have no feedback or the feedback arrives late will lead to overwork, waiting and most important of all, dissatisfaction of our customers.

What do we do to operate this lever?

First of all, determine what feedback we need.

Do I need formal feedback? One continuous? A positive one? Okay? This is the first thing. Understand what feedback I need. Because, many times, we give a lot of feedback already, but is it worth it to the team? Does it do us any good? Does this feedback really impact the decisions the business will make? Because if it is not to have an impact, then we are surely wasting time.

Second action we can do here: move the revisions to the left.

In the value chain the idea is that the need arises from the left and moves in production to the right. Here what we want is the reviews the further to the left, the better.

I don’t have to wait until the entire product is complete to do a pre-review. Okay? I can do it the moment we have something, so hey, we can show it, we can verify it, we can see it. It’s not like, until the end of the sprint, until the end of the quarter, until I don’t know where, I won’t have the feedback.

Third action, shows the system working. We need to empirically validate what we have done. This is not about, imagining that a product or system is one way or the other. We show it!

We show what we have, let’s capture their sensations. Once again, let’s visualize how our work is done.

5th Efficiency: Working small sets of elements.

Working in groups of very large elements will cause queuing, long waiting times, long waiting times, customer dissatisfaction, increased risk, decreased predictability and increased variability.

This is very bad, we want to avoid it!!!!

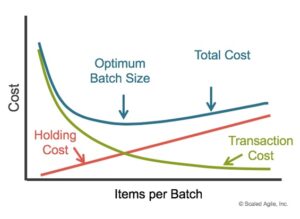

There is a chart that can help us to understand and select the work of small elements as a whole.

Have you ever seen this chart? This tells us that we can paint a series of lines based on two axes. One in cost, either time or money. And the other on the number of elements we have per batch.

And we get two costs:

The holding cost, which is the cost of not having something in production, I don’t care if I will have it tomorrow, if I will have it in a minute or if I will have it a year from now. But since I don’t have it now, it now has this cost.

And the other is the transaction cost, it is how much it costs me to move an item from one state to another.

Adding these two costs together tells us the optimum batch size.

If anyone has ever wondered:

“hey, how can you calculate the optimal wip limit with these formulas?”

“Yes”

“And how do we get this?”

“Empirically. It’s not that easy, sorry.

”

So, I if I add the two costs together, the lower point of the line is the optimal batch size.

What can we do here?

Work and cadences at all levels. If we limit the temporal space in which we work, this temporal space limits the amount of elements you can put in.

If I tell you, do you have an hour to make dinner? You will have one hour of dinner. If I tell you that you have 10 hours to cook, then you will have many more elements in progress.

The idea is to have this, cadences at different levels. Apart from the fact that we can have teams working with one cadence, we can have teams of teams working with another cadence, which will help us a lot to work with smaller groups.

Next action we can do on this lever is to adjust the process to support the small batch.

Why don’t I plan more often? Why don’t I put…?

I don’t work with sprints. Okay, but instead of planning what you’re going to do for half a year, plan what you do for the next month.

Although there are no sprints, but by planning often what we are doing is reducing the number of elements. And if we reduce the number of elements, we will reduce the amount of things our team will be scattered around working on.

Another way we have?

So work by iterations. What we said at the beginning.

Third action, automate. And this is the key to the above graph. The holding cost, I cannot modify it, because it is the cost of not having something. And I don’t have it, so it is not affected.

But I can transaction cost. If I am able to make the step from state 1 to 2 smaller, this line will go down, the green line will be smaller, and then the optimal batch size will move further to the left. And this we will have, smaller batches, optimizing costs.

Automation is very, very important.

It is a cost, yes!

Well, it is a cost but it is amortizable, because if you automate you will be able to work in smaller groups of elements and you will avoid all these problems.

6th Efficiency: Reduces waiting lines.

A queue is nothing more than an amount of work committed at some point.

I really like to ask, is there anyone who has ever been in a queue, except at a concert, who has been super happy? Probably not, we don’t like to wait.

This same question when I asked it in Iceland I was told, yes, of course, when you haven’t seen people for a long time because you live a few kilometers away we like it.

Queues are not good for systems, they are not good for organizations. A waiting queue leads to delays, increased risk, lower productivity, lower team motivation.

So, here what we can do is some actions.

First of all, prioritize by objectives. Why can’t I link this to OKRs? We analyze my entire backlog list, everything I have to do and everything that… and everything that is not aligned with the objectives, out:

I have just reduced the waiting time for many items. Anything that does not contribute to this objective, out.

Anything we need that is not a priority, we take out.

We can’t delete things from our system, let’s move it to a Someday Maybe and when it has been in Someday, Maybe for 5 years, then we delete it.

Second thing we can do, work in iterations.

Working in iterations is tricky. It will certainly not reduce queue length, but it will increase predictability. If I know that in each time slot a number of elements will enter, if mine is in position XX, I know that so many will pass before, so I will have predictability.

Many times, the problem is not the queues, the problem is knowing how long to wait.

Working in interactions, what will help us is to have predictability on waiting times.

And the third action we can take on this lever would be for all demand to enter through a single point.

And it is also linked to the first one. If we have different entry points of demand, if we have different people asking.

No, one asks me for Slack, no, the other one asked me for the coffee machine, the other one for an email, the other one… All this will cause us to have a lot of queues. Again, having a single point of entry does not mean that you will have less queues, but it does give a true picture of what you will have to wait for or what our stakeholder or whoever will have to wait for to have the different requests available.

7th Efficiency: Optimizes “Focus time”.

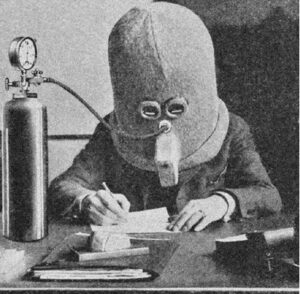

This you see here is the Isolator. It is a helmet designed by a science fiction writer in 1925.

With this invention he was able to be much more productive in his writing. It’s a hull made of wood that insulated him 95% from outside noise and he had two glass peepholes here for viewing and he actually had an oxygen supply here. Why? Because he realized, wow, when I’m focused, I’m much more productive.

It is very important to understand that, if a team or a person manages to have quality time focused on a series of tasks, it increases their creativity, efficiency, productivity and happiness.

So what can we do here to increase flow time? Focus Time.

First, optimizemeetings!

Have any of you ever felt this way? How many organizations have meetings? Let’s have a meeting!

Everyday meetings, no agenda, no guests, no topics to discuss. First of all, if we want to optimize the focus time, we have to optimize the meetings. Many times we are working on something and you say, if I have a meeting in half an hour, I can’t even get started.

Why? Because I know that the cognitive load of putting myself to work on something is going to be such an effort that in half an hour I’m already going to have to go there, so I don’t care.

One idea that is a bit crazy, but works well, is to protect the equipment. That the team has a pomodoro, a time in which they do not have meetings all afternoon.

Or all morning, from 10 to 2 there are no meetings. To be able to have these spaces, for example.

Another action we can do here is to reduce the WIP.

The number of items in progress, third time out.

Well, maybe it is important and maybe this can give us some effects that we can’t imagine.

Dare to try a WIP!

If I have several elements to work on and they are few, I will be able to be much more focused on those few than if I have a lot of them. Well, I encourage you, if you only have to try some of this, make it WIP.

Another is to look for collaboration tools.

Let’s have the right channels, let’s use per-programming, let’s use group work, let’s use these types of elements that allow us to be focused on the same task at the same time. This will maximize the creativity of our teams. And productivity, of course.

One more action, let’s make a good product.

If you make a good product with quality, the amount of incidents, or interruptions, or unplanned demand, that will reach you will be less. Thus, the team will be able to work on its own for a longer period of time.

It sounds silly, but it’s not. A good product will help us to make the team more productive in the background. Ah, but there is no time.

Skip this quality thing and we’ll get to it. It’s going to hurt you here.

8th Efficiency: Influencing company policies

And last but not least, influencing existing policies.

Many times, when we are trying to change the way we do, what we do is add more and new practices.

And what does this cause?

People who don’t know what to do, right? Paralysis, overload…

We have to understand that what we have to look for is to do something different, not to add more things to them.

What can we do here?

Well, first of all, let’s focus on the flow impediments, now that we have identified them, and talk about them.

Let’s not try to change policies per se, let’s have a reason, let’s use metrics.

Metrics, something to say, here’s a problem and we’ll act on it, okay?

And finally, think read.

In any process we will have steps that add value or policies that add value, others that do not add value but are necessary, and others that do not add value and are not necessary.

Why do we make them? Because they have always been done that way. And this is what we must try to avoid.

Conclusion

These 8 levers will help us improve the efficiency of our work environments. There is one piece of bad news, though:

This is not as easy as applying all the actions of the 8 levers all at once.

But it is about testing some actions within the different levers to carry out an incremental iterative change.

And if in this process, you need help: contact us, we will be happy to help you!