Can you imagine being able to make your company’s processes run better, faster and with fewer errors? That is exactly what Lean can do for you. It is not a methodology, but a way of thinking and working that seeks to eliminate waste, optimize resources and achieve more efficient results in everything you do.

In this article, we’re going to explore some of the most useful tools within Lean, those that will help you make everything run more smoothly and effectively. From the famous 5S method to value stream mapping (VSM), here you will find the “survival kit” your company needs to remain competitive and efficient.

What is Lean Management?

Lean Management is a management philosophy that focuses on maximizing customer value while minimizing non-value adding activities. It originated in Toyota’s production system, where it was designed to optimize production in a context of scarcity after World War II. Today, Lean Management is applied in all types of sectors, with companies such as General Electric, Nike or Amazon.

Reducing shedding: key to efficiency

The main focus of Lean Management is to reduce what is called Mudas, a Japanese term that refers to all those activities that do not add value to the product or service from the customer’s perspective. These activities generate waste that not only affect operational efficiency, but also increase costs and reduce the company’s competitiveness.

There are seven types of mutations that may be negatively impacting your organization’s bottom line:

- Overproduction: Producing more than what is needed, which consumes resources without providing immediate value to the customer, increasing costs and risks of obsolescence.

- Excessive inventory: Storing unnecessary materials or products that are not immediately used and tie up capital that could be invested in improvements that the customer values.

- Waiting times: Delays between processes that slow down delivery to the customer, decreasing the speed of response and creating inefficiencies in the flow.

- Unnecessary transportation: Unnecessary movement of products or materials, which adds time and risk of damage, without improving quality or value perceived by the customer.

- Over-processing: Performing more work than necessary or repeating tasks, which obviously increases costs without providing additional benefits.

- Unnecessary movement: Unnecessary movement of people or tools, which generates inefficiencies that do not contribute to the value of the product.

- Defects: Defective products require corrections that consume time and resources, delaying delivery and compromising the quality expected by the customer.

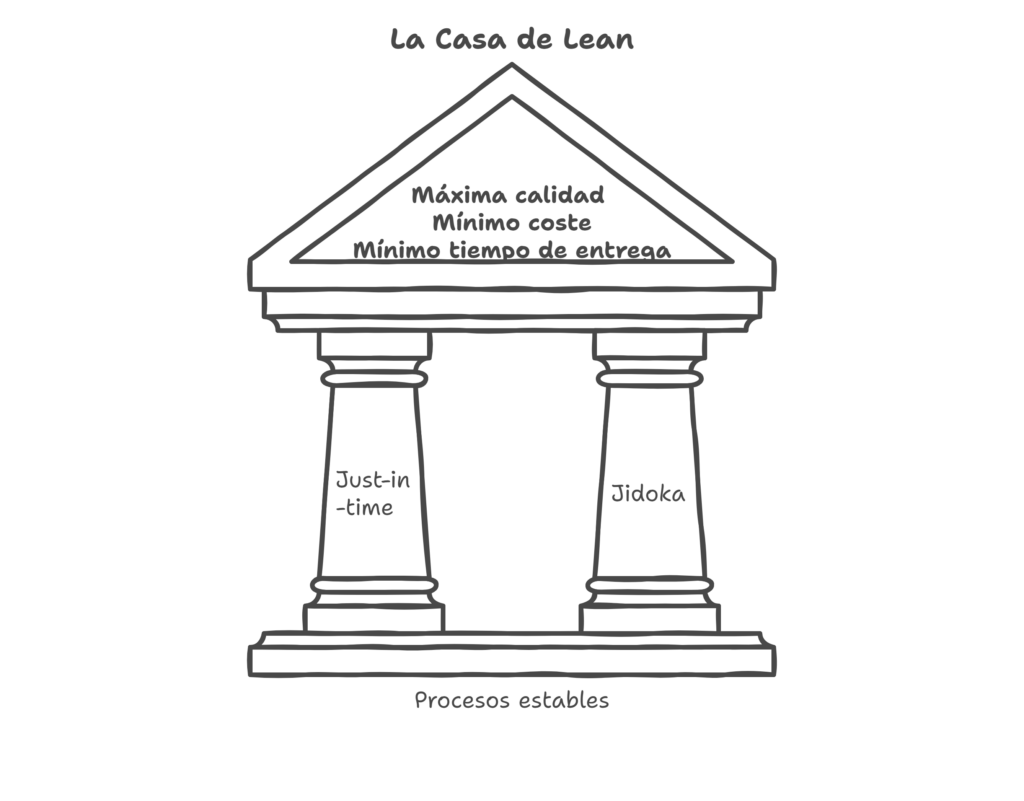

Lean Management is based on five fundamental principles that guide its implementation:

- Identify the value

- Mapping the value stream

- Create a continuous flow

- Establish a pull system

- Pursuit of perfection (kaizen)

Based on these principles, multiple tools are deployed to help implement them effectively. In the following, we will explore some of the most commonly used ones.

Principle 1: Identify the value

The first step in Lean is to understand what really matters to the customer. With this knowledge, it is possible to focus efforts only on those activities that add value. To achieve this, key tools are available to capture what the customer values, visualize the customer journey and adapt the business model to better meet the customer’s needs.

Voice of the Customer

Voiceof the Customer (VOC ) is a tool for gathering and understanding directly the customer’s needs, expectations and pain points. This is done through surveys, interviews, social network analysis or focus groups. By systematically listening to the customer, companies can align their products and services with what their customers really value.

Customer Journey

The Customer Journey is a visual representation of all interactions between the customer and the company. By mapping this journey, you can identify moments where the customer perceives value and friction points that need to be improved. The process begins by documenting each touch point from the time the customer discovers the product to after-sales service, allowing the company to adjust the process to improve the customer experience.

Lean Canvas

The Lean Canvas is a strategic planning tool that allows you to visualize all the key elements of a business model on one page, focusing on the customer. The process starts by identifying the core customer problem, then the value proposition is defined and aspects such as customer segments, channels, key metrics and cost structure are analyzed. This allows companies to quickly assess the viability of their business model and adjust elements that do not provide value to the customer.

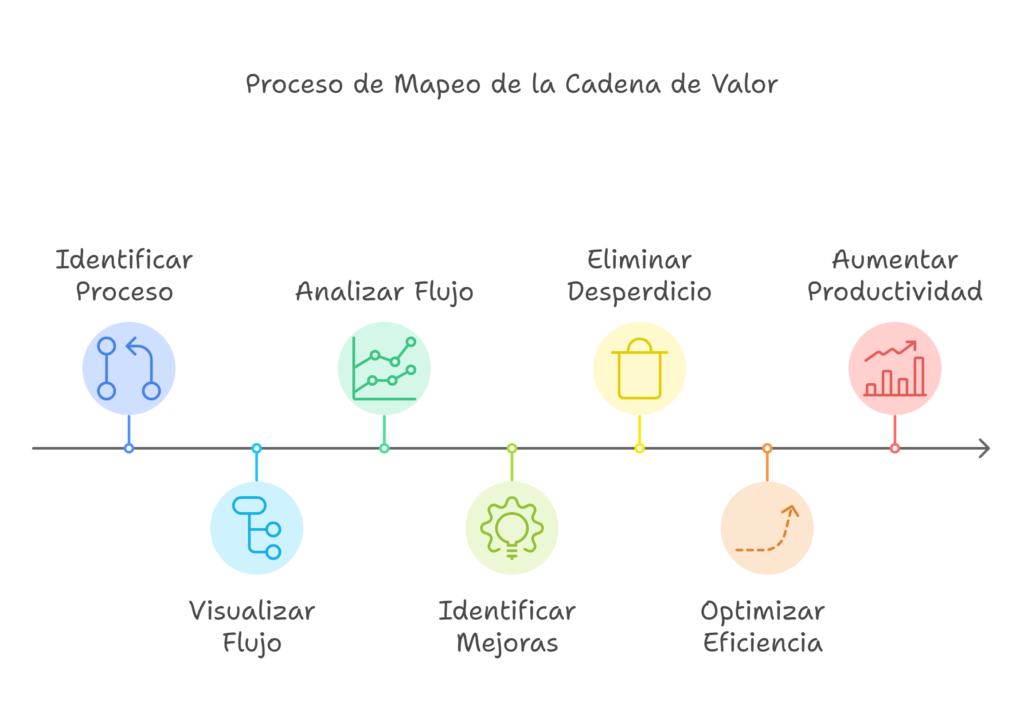

Principle 2: Value stream mapping

Once value has been defined, the next step is to visualize the entire process that leads to the delivery of that value to the customer. Value stream mapping helps to identify both the activities that add value and those that do not. The tools discussed below are essential to map this flow effectively.

Value Stream Mapping

Value Stream Mapping (VSM) is a visual tool that allows mapping every step and activity involved in the production or delivery of a service or product. By mapping all activities from inception to final delivery, it identifies those that add value and those that do not, along with their execution times. This map provides a clear view of opportunities to improve workflow and reduce slippage.

SIPOC analysis

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) is a tool that provides a global view of the process. It starts by identifying thesuppliers (Suppliers) and theinputs (Inputs) used in the process(Process), up to the final results(Outputs) and the customers who receive the value(Customers). SIPOC helps to understand all the elements involved in the creation of value, facilitating the identification of improvements at each stage.

Principle 3: Create a continuous flow

After analyzing the value stream, the challenge is to make it move smoothly, without interruptions or bottlenecks. A seamless flow ensures that value reaches the customer faster and with less effort. Next, we will review some tools that facilitate this flow optimization, promoting more agile and efficient processes.

SMED (Single-Minute Exchange of Die)

SMED (Single-Minute Exchange of Die) is a technique designed to reduce the time required to switch from one task or process to another, ideally in less than 10 minutes. It works by separating tasks into internal (which require stopping the process) and external (which can be performed while the process is still active). Then, internal operations are optimized and standardized, converting as many tasks as possible to external. This reduces downtime and improves efficiency in any type of environment.

Spaghetti Diagram

The Spaghetti Diagram is a visual tool that plots the flow of work within a process, showing the path of people, materials or information. Lines are drawn to represent each movement, which helps to identify inefficient routes, redundancies and bottlenecks. This visual analysis simplifies movements, reducing time and effort, and optimizing process flow.

Principle 4: Establish a pull system

The next step is to ensure that only what is needed, when it is needed, is produced. This reduces unnecessary inventories and avoids overproduction. The tools presented below help to implement this pull approach, ensuring production in line with customer demand and improving overall efficiency.

Kanban

Kanban is a visual system that organizes the workflow, allowing to produce only what is needed, when it is needed. Through visual cards on a board, tasks move through the different phases of the process, limiting work in progress(WIP) to avoid bottlenecks. Kanban helps maintain a constant and efficient workflow, linked to customer demand, and prevents overproduction or unnecessary backlogs.

Heijunka Box

The Heijunka Box is a visual tool that helps level the workload over time, avoiding peaks and troughs in production. It functions as a grid where cards representing products or tasks to be completed at specific intervals are placed. By evenly distributing production over time, work overloads and downtime are avoided, improving flow and efficiency.

Principle 5: Pursuit of perfection (Kaizen)

Continuous improvement is the last principle and the one that unites all the previous ones. The Lean process never stops, there is always room for optimization and elimination of sluggishness. The tools we will see below are designed to encourage continuous improvement, involving the team in the constant search for perfection.

Retrospectives

Retrospectives are regular meetings where the team reflects on its recent work, identifying areas for improvement and planning actions for future iterations. During these meetings, the team discusses both achievements and problems, looking for opportunities to improve processes. Retrospectives encourage continuous improvement and reinforce the culture of collaboration and improvement within the team.

If you can only do one meeting: make it an Agile Retrospective (and don’t blow it) – Smartway

The 5 why

The 5 Why’s is a technique that delves into the root cause of a problem by asking repeated questions. It starts with the question Why did this happen and the answer leads to the next question. This process is repeated until the root cause of the problem is found, usually after five questions. By getting to the root cause, the team can design lasting solutions that address the problem at its source, rather than just treating the symptoms.

Ishikawa Diagram

The Ishikawa Diagram, or fishbone diagram, is a tool used to identify the root causes of a problem. A main fishbone is drawn with branches representing different categories of causes, such as People, Methods or Materials. Then, within each branch, more specific causes are identified. This visual diagram allows the team to focus on the critical causes and design solutions that eliminate the problem at its source. This tool, combined with the previous one, is one of the most powerful tools for uncovering root causes.